The manufacturing of basketballs

The manufacturing process of a basketball is similar for every manufacturer. Here is a short overview of the process.

1- Sheets of black rubber are used to form the "bladder", the innermost layer of the basketball that will hold the air.

2- A hole is punched in the rubber where the air tube will be inserted

3- The rubber is cut into shape and the edges are bound together. This bladder is not perfectly shaped.

4- The bladder is taken into a vulcanizing machine where it will be heated to make it more flexible, durable and stronger. There it is inflated and will be stored in a chamber for 24 hours to make sure that it does not deflate.

5- If it passes the test, it is brought to the twining or winding department. There, machines loaded with spools of either polyester or nylon thread wraps multiple strands around the bladder. With this process, the bladder takes on a more uniform and round shape. (The quality of the thread and the number of strands determine the cost and quality of the ball)

6- Meanwhile, a machine is used to punch out shapes on colored rubber.

7- The cut out shapes are put into the vulcanizer, where the finished and glue coated bladder is placed. The shapes and the bladder are glued together.

8- Balls are inspected and decoration and information can be applied to it by hand or with small heat presses.

9- The ball is placed one last time in the vulcanizer where its surface will be unified and where it will acquire its "peppled" surface.

10- The ball then passes another 24 hour test to make sure it stays inflated and eventually needs to pass a bounce test before it is deflated and shipped off.

If you wish to see how a basketball was manufacture in the 1930's (the process was similar to what it is now) watch the link below.

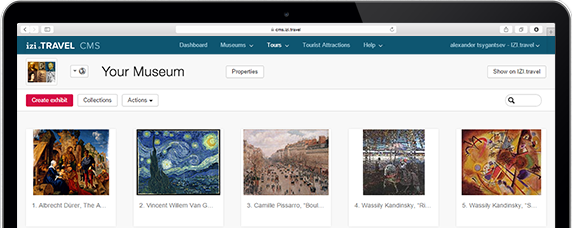

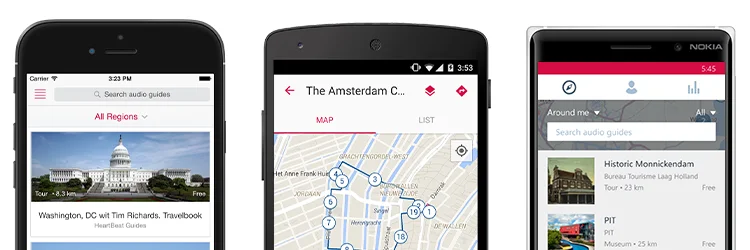

Download the free izi.TRAVEL app

Create your own audio tours!

Use of the system and the mobile guide app is free